- Jialong

- China

- 15 working days

- 100 sets per month

Fully Automatic Animal Feeds Bagging Machine

1.Double working station bag giving system. 100-300 bags can be stored.

There are detectors for alarm if either of the working station’s bags is finished.

2.There is an air pressure detecting device in the process of picking up the bag, opening the bag, clamping the bag, and filling the bag. Unqualified bags will be kicked out automatically without stopping the working.

3.Bag-clamping movement and discharge gate are using two independent systems which make the bag clamping more stable. Animal feeds packing machine

4.Using the big finger cylinder can make sure the bag mouth to be smooth.

5.It adopts a plastic chain plate conveyor belt, gear meshing transmission, which is not easy to slip and deflect; the conveyor belt and the upper guide bag mechanism adopt mechanical linkage to ensure the synchronization of the conveying process. Fully automatic Feeds Bagging Machine;

6.All the major motoring is using servo motors. It’s very easy to adjust for different packing specifications, no need manual adjustment.

ZDB-600-Q9 Fully-auto Bagging Machine

Fully Automatic Animal Feeds Bagging Machine

i. The full set includes

Description | QTY | |

Auto Bag-giving machine | 1 set | |

High-speed weighing scale | 1 set | |

Packing machine | 1 set | |

Conveyor with a stitching machine (1 set) | folding machine | 1 unit |

Stitching machine | 1 unit | |

ii. Main configure:

Product description | Configuration |

Touch Screen (weighing controller) | Switzerland / Mettler Toledo |

Load Cells | USA/Celtron |

Power Switch | Japan/Omron |

Limit switch | Japan/Omron |

Miniature Circuit Breaker | France/ Schneider |

button、knob | France/ Schneider |

intermediate relay | Japan/Omron |

cylinder | Taiwan/AirTac |

Electric cylinder | Japan/SMC、IAI |

solenoid valve | Taiwan/airtac |

Servo motor | Japan/ Panasonic |

Vacuum pump | Germany/leybold |

Stitching machine | China/Bafang (optional: Japan/Newlong) |

iii. Technical Parameters

Packing speed | 400-500 bags/hour |

Package weight | 25-50kg |

Bag range | L:880-1000 W:550-600 (reference) |

Applicable materials | Granular materials such as rice |

Air pressure | 0.4-0.6MPa |

Power | 380/220VMPa |

Power Consumption | 6KW |

iv. Bag requirements

The basic requirements

1. the front and back hardness of the bag can not be too different (the specific test is subject to the actual test)

2. mouth bag not sticky

3. bag and bag corners are flat and thickness is good

4. need bag samples before the final confirmation.

5. non-laminated bags also ok

v. Function and features

1. Double working station bag giving system. 100-300 bags can be stored. There are detectors for alarm if either of the working station’s bags is finished.

2. There is an air pressure detecting device in the process of picking up the bag, opening the bag, clamping the bag, and filling the bag. Unqualified bags will be kicked out automatically without stopping the working.

3. Bag-clamping movement and discharge gate are using two independent systems which make the bag clamping more stable, Animal feeds packing machine

4. Using the big finger cylinder can make sure the bag mouth to be smooth.

5. It adopts a plastic chain plate conveyor belt, gear meshing transmission, which is not easy to slip and deflect; the conveyor belt and the upper guide bag mechanism adopt mechanical linkage to ensure the synchronization of the conveying process.

6. All the major motoring is using servo motors. It’s very easy to adjust for different packing specifications, no need manual adjustment.Fully automatic Feeds Bagging Machine

vi. Product Photo

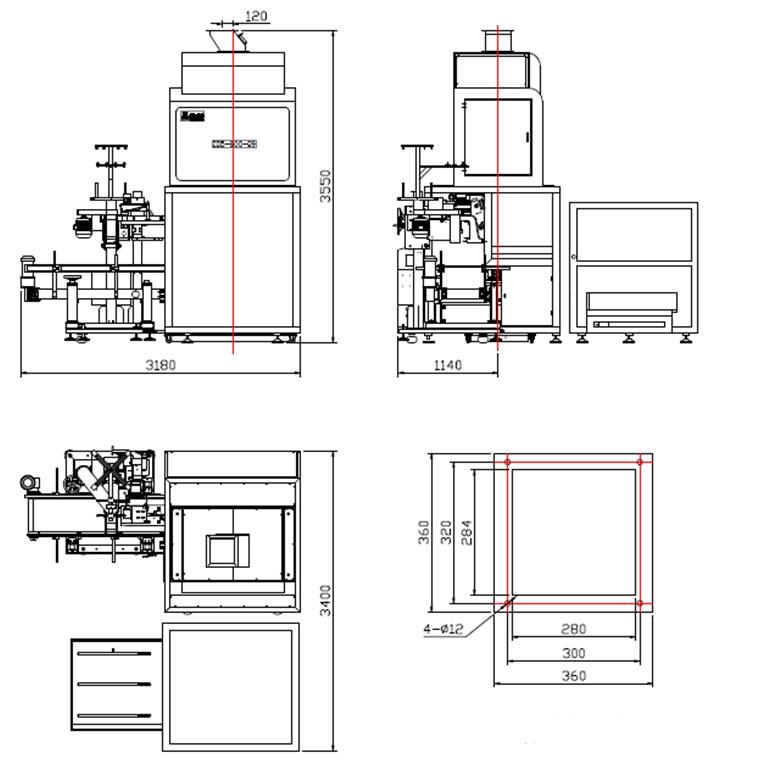

vii. Installation size: