- Jialong

- China

- 30 working days

- 100 sets per month

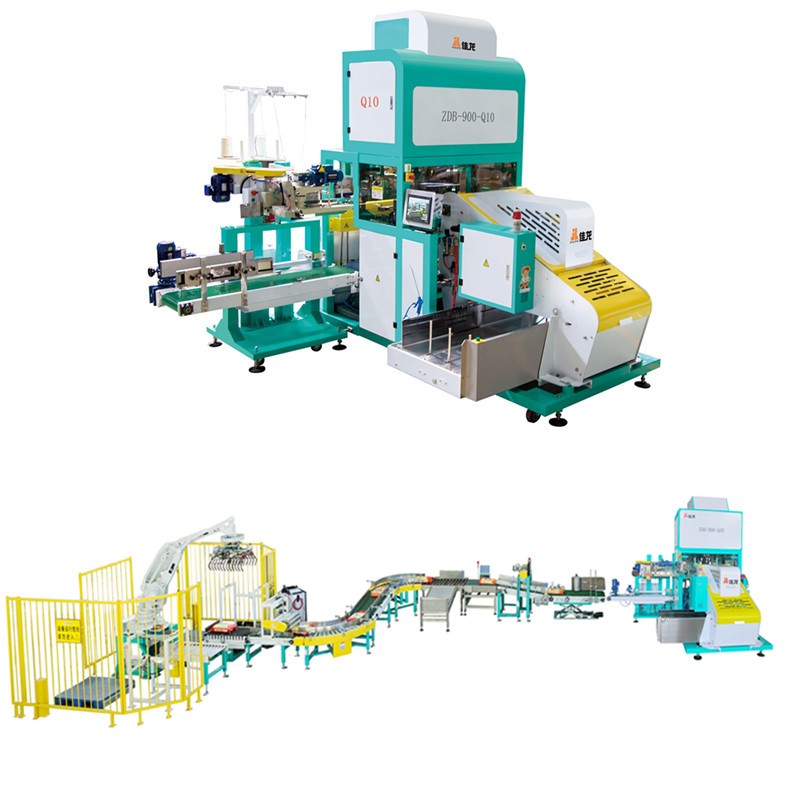

25kg–50kg PP Woven Bag Rice Packing Machine & Packaging Solution Line

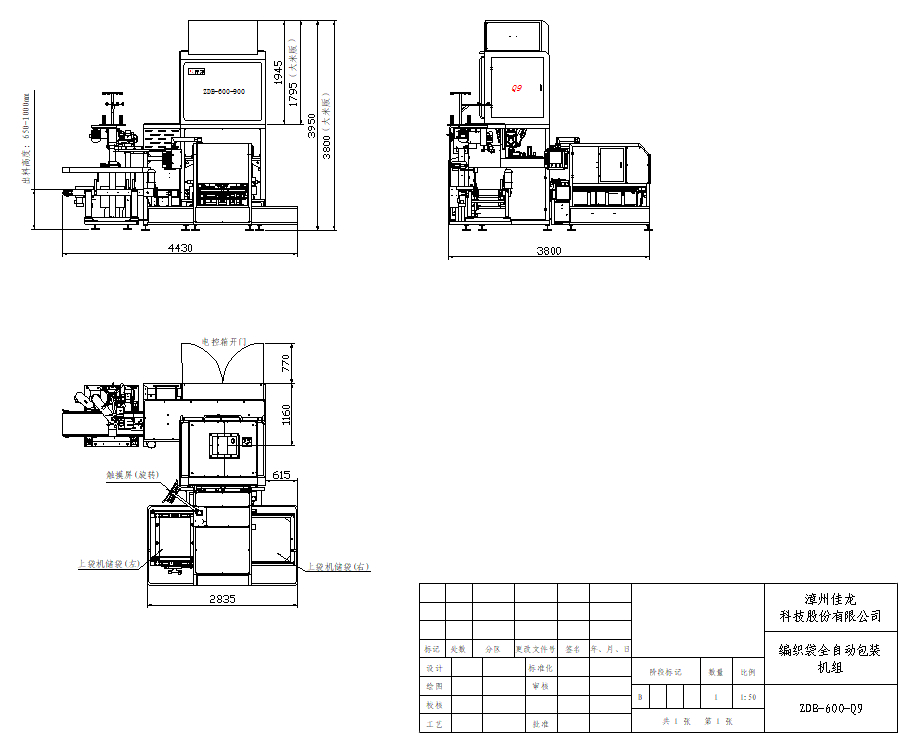

- Product Model: ZDB-600-Q9

- Packing Range: 25-50kg

- Packing Speed: 500-600 bags/h

- Application: Rice, Grain, Soybean, Peanut, Wheat, Feed, Millet, Corn, Seeds Lentil, Coffee Pod, Cashew Nuts, Salt, Tea, Flour, Fertilizer, Barley, Oats, Maize, Rye, Sunflower, Rapeseed, Linseed, Sorghum, etc.

25kg-50kg Rice Packing Line Solution Bagging And Packing Machine Factory China

Product description:

ZDB-600-Q9 packing machine for 25-50kg open-mouth pillow and/or gusseted bags for woven PP and paper bags.

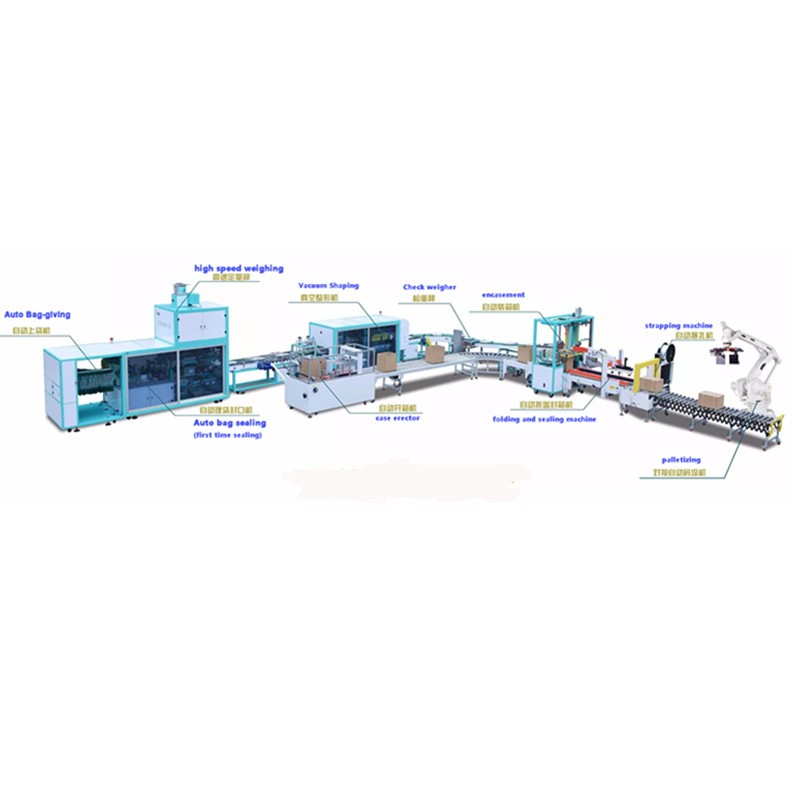

The full st Rice Packing line solution include: automatic weighing packing machine, Bagging, stitching, conveyor, Metal detector, weighing scale, robot palletizing ect.

It is distinguished by its outstanding speed and reliability as well as its high flexibility to work with all kinds of bag types and materials. Due to its technical maturity and several patented modules, the bagging system has become one of the most reliable packaging machines in the world. The bagging machine has been therefore installed in many different industries for packaging products like plastic pellets, animal feed, corn, seed, beans, lentils, sugar, rice, and so on.

The full set includes:

Description | QTY | |

Auto Bag-giving machine | 1 set | |

High speed weighing scale | 1 set | |

Packing machine | 1 set | |

Conveyor with stitching machine (1 set) | folding machine | 1 unit |

Stiching machine | 1 unit | |

Main configure:

Product description | Configuration |

Touch Screen (weighing controller) | Switzerland / Mettler Toledo |

Load Cells | USA/Celtron |

Power Switch | Japan/Omron |

Limit switch | Japan/Omron |

Miniature Circuit Breaker | France/ Schneider |

button、knob | France/ Schneider |

intermediate relay | Japan/Omron |

cylinder | Taiwan/AirTac |

Electric cylinder | Japan/SMC、IAI |

solenoid valve | Taiwan/airtac |

Servo motor | Japan/ Panasonic |

Vacuum pump | Germany/leybold |

Stitching machine | China/Bafang (optional: Japan/Newlong) |

Technical Parameters:

Packing speed | 500-600 bags/hour |

Bag range | Length:730-1100; width 330-650 mm |

Package weight | 25-50kg |

Applicable materials | Granular materials such as rice |

Air pressure/consumption | 0.5-0.6MPa 26m³/h |

Power | 380/220V 3phase,five wires |

Power Consumption | 9KW |

Bag storage | 100-300 pcs |

Function and features:

1. Double working stations bag giving system. 100-300 bags can be stored. Rice Packing line solution

There are detectors for alarm if either of working station’s bags are finished.

2.There are air pressure detecting devices in the process of picking up the bag,

opening the bag , clamping the bag and filling the bag. Unqualified bags will be kicked out automatically without stopping the working.

3. High speed weighing scale.

4.Bag-clamping movement and discharge gate are using two independent

systems which make the bag clamping more stable

5. Using the big finger cylinder can make sure the bag mouth to be smooth.

6. It adopts plastic chain plate conveyor belt, gear meshing transmission, which is not

easy to slip and deflect; the conveyor belt and the upper guide bag mechanism adopt mechanical linkage to ensure the synchronization of the conveying process.

7. All the major motoring are using servo moters. It’s very easy to adjust for different

packing specifications, no need manual adjustment.

8.Contact parts in stainless steel

9. Reliable and proven concept; Sturdy and compact design

10. High flexibility

11.Bag magazine bag separation bag opening bag placing bag filling bag closing bag trasnport

12.Unique, advanced, fast and versatile bagging equipment.

13. Granular materials into open-mouth bags, has no equivalent on the market. The operating principle of this bagger makes it one of the fastest bagging machine in the world. It can handle a wide variety of products and bags for optimal flexibility

14. Minimal bag handling time to allow high speed operation

15. Total control of the bag during the entire cycle

16.Programmable logic controller (PLC) with user-friendly, touch-sensitive operator interface for easy troubleshooting and error code reading

17.Multiple-stack bag magazine for great operating autonomy fast and easy reloading options

18.Tool-less changeover for multiple bag sizes

19. Bag closing systems and weighing system

Automatic bag filling machine, Machine packaging rice, Fully automatic packing machine

Product Photo:

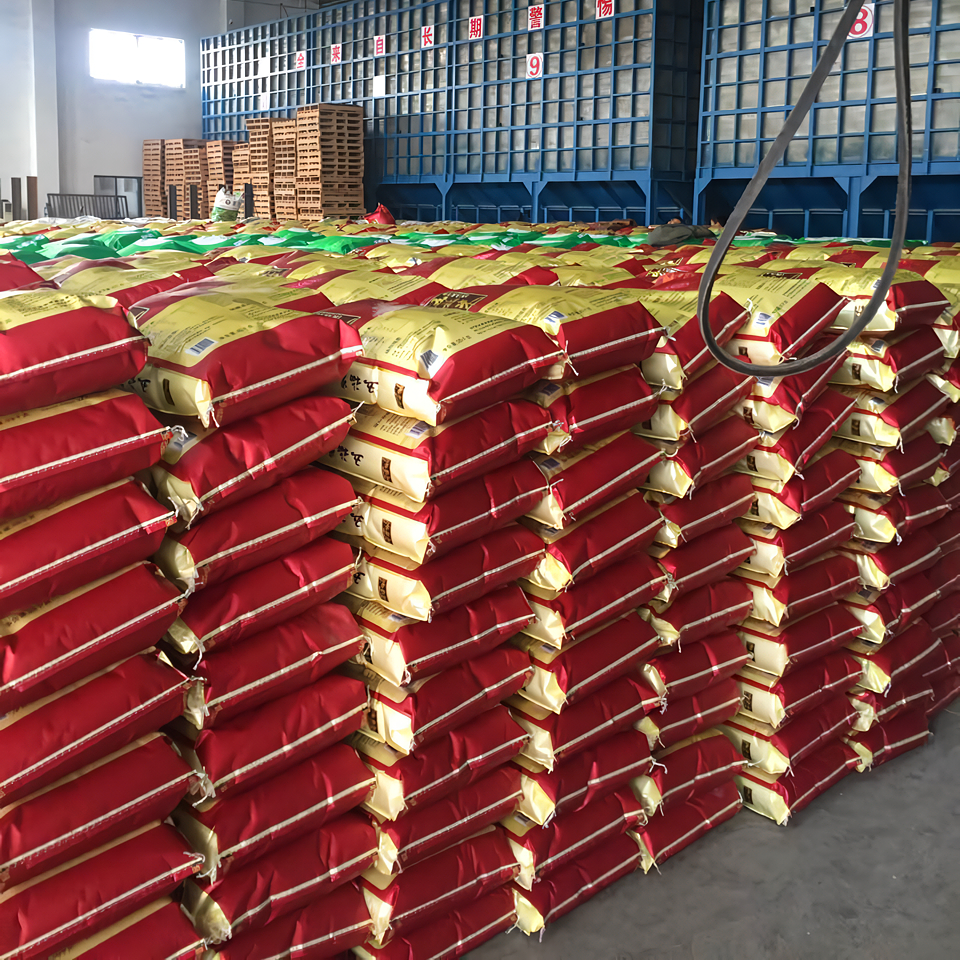

Projects reference: