- Jialong

- China

- 20 working days

- 1000 sets per month

This production line is in accordance with the conventional bagging process configuration, the entire production process a high degree of automation, in line with China GMP health standards;

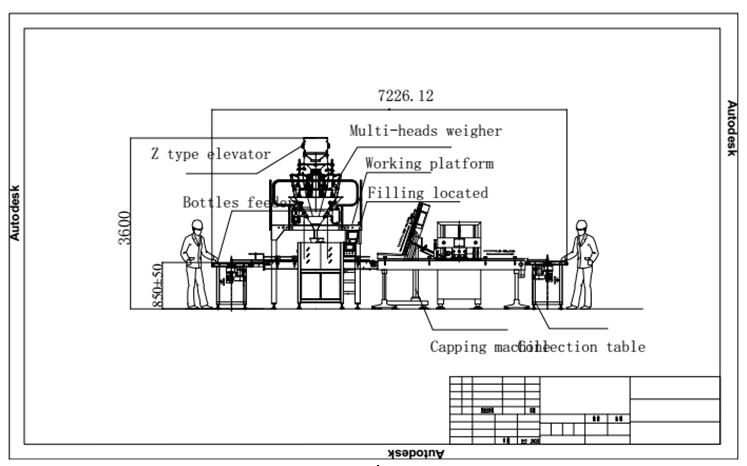

Cans feeding table → Z type elevator → 10*1.3L multiheads weight → Working platform → Cans rotary located filling machine → Cans covering and sealing machine → Videojet printing machine → Cans collection table

Automatic Cans Weighing and Filling Packing Line

Crafting process:

Cans feeding table → Z type elevator → 10*1.3L multiheads weight → Working platform → Cans rotary located filling machine → Cans covering and sealing machine → Videojet printing machine → Cans collection table.

Technical Parameters:

l Product: granular products

l Packing type: cans

l Packing weight: 400g

l Weighing accuracy: ±1.0g

l Packing speed: 30~35 bottles/min

l Machine frame material: SS304

Application:

This production line is in accordance with the conventional bagging process configuration, the entire production process a high degree of automation, in line with China GMP health standards;

Introduction to the production line:

l The production line supporting machinery in addition to marked materials are stainless steel, all machine structures are in accordance with food hygiene standards selected design;

l The material contact with the container material are food grade SUS304;

l Often dismantling the structure are easy to dismantle the connection, to ensure that the shift or change the product when dealing with health convenience;

l The production line of the normal production needs 2~3 employees. The above program for customers to change, please notify the relevant person in charge of the Company, do the relevant adjustments.

Pictures: