What problems does the automatic packaging machine solve for the enterprise

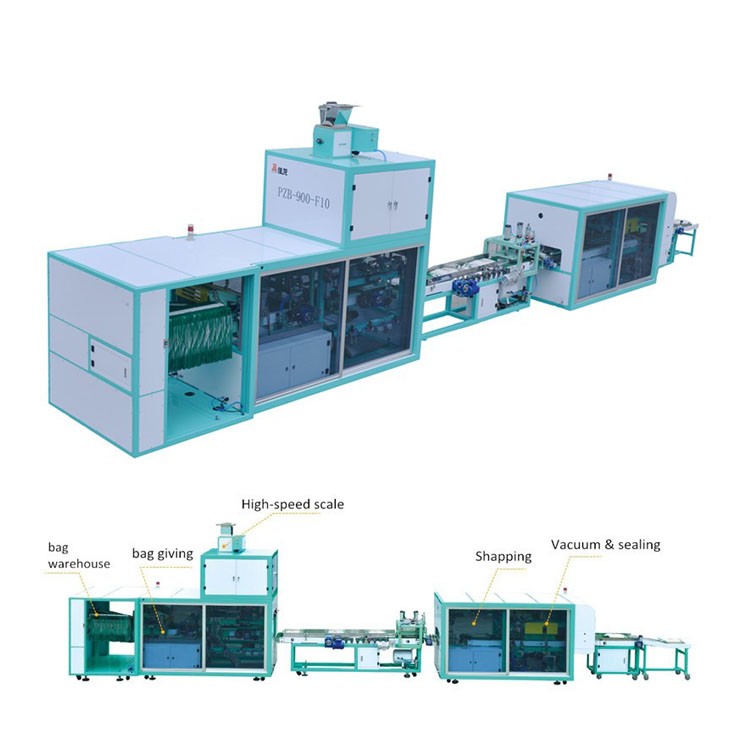

An automatic packaging machine is a machine designed to automatically pack products into pouches, pouches, boxes or cartons. It is commonly used in the food, beverage, pharmaceutical and cosmetic industries to package products such as snacks, confectionary, powders and liquids. So what packaging problems does the automatic packaging machine solve for the enterprise?

1. High efficiency: In the past, the production efficiency of traditional manual packaging was relatively slow, and it was easy to lose materials. Using automatic packaging machines instead of manual packaging can efficiently complete the production processes such as feeding, measuring, bagging, printing dates, and product output. Automatic packaging machines increase the speed and efficiency of the packaging process, reducing the time and labor required for packaging.

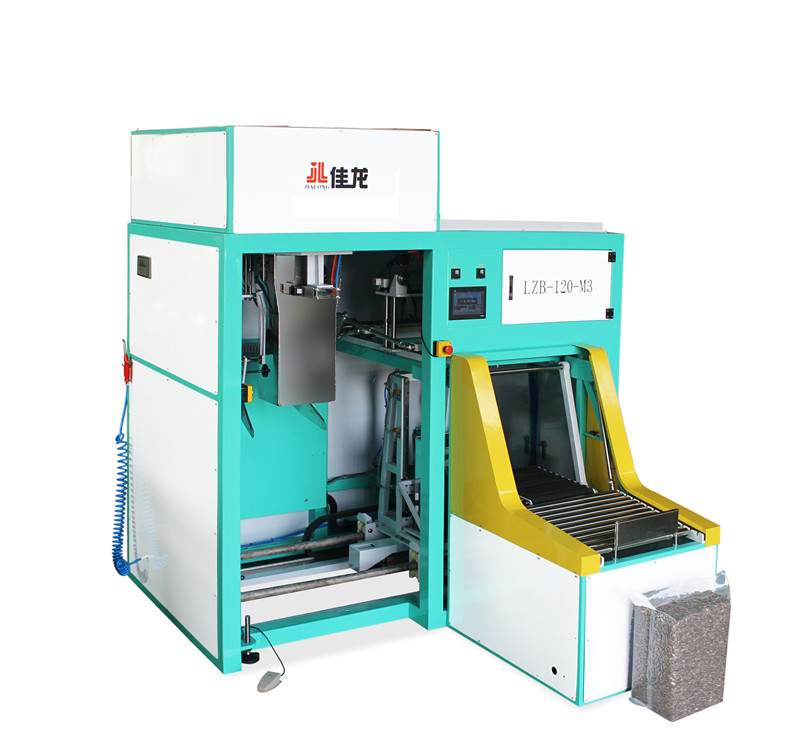

2. Cost saving: the use of automatic packaging machines has high measurement accuracy, fast efficiency, saves materials, reduces manual labor, and saves costs for enterprises.

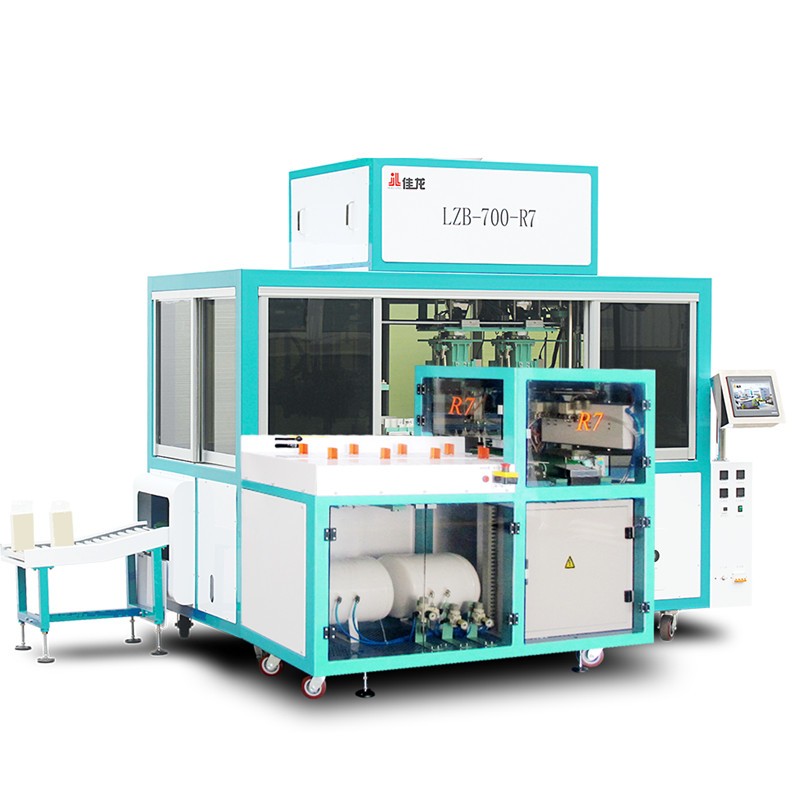

3. Increased productivity: These machines can handle large volumes of packaging, increasing productivity and output.

4. Safety and sanitation: It is difficult to avoid human-to-human contact in manual packaging, and the production of products is easy to contaminate products due to manual participation, and the production quality is difficult to guarantee. Automatic packaging machine Automatic production from incoming materials to finished products without human involvement, reducing the risk of work-related injuries and accidents associated with manual packaging. It reduces the bacterial pollution in the packaging process and provides a good guarantee for the enterprise.

5. Environmental impact: Generally, automatic packaging machines with good service have the function of automatic detection. Therefore, for those unqualified products, the machine can intelligently and automatically screen and repack again, which not only improves the pass rate, but also does not waste materials. It is also easy to maintain and operate, reduces packaging waste and optimizes the use of packaging materials, resulting in a positive environmental impact.