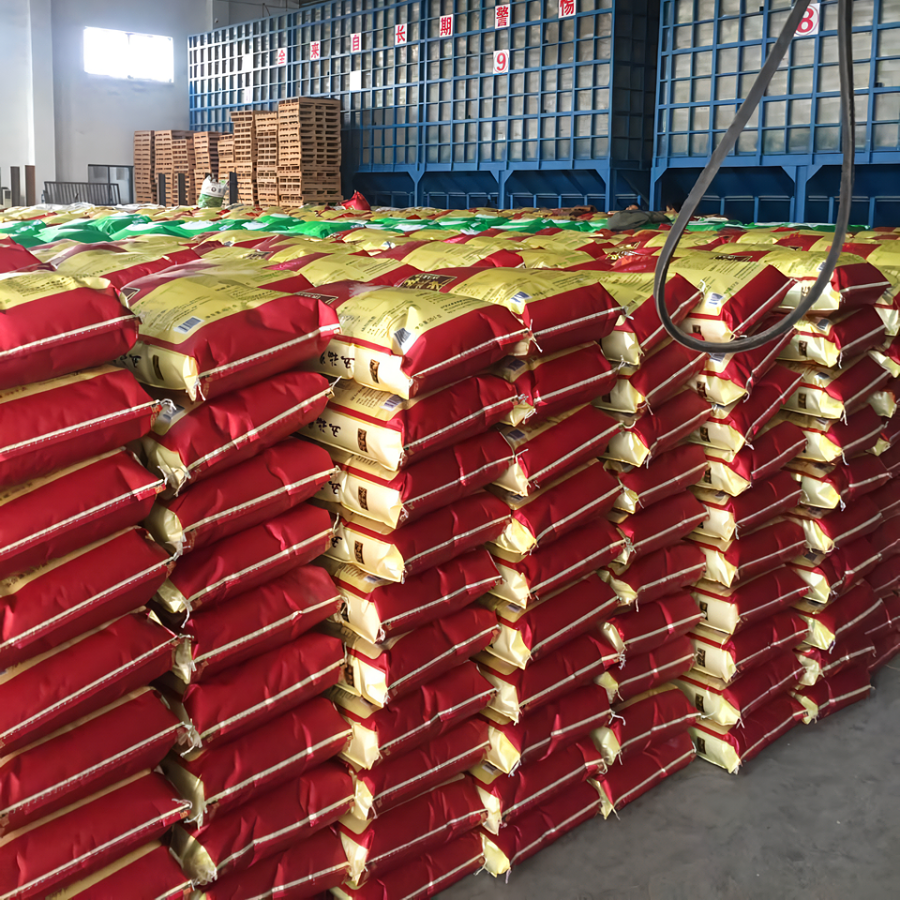

Simplify rice packaging with high-speed efficiency

In the fast-paced world of food production, efficiency and precision are critical to meeting consumer demands and maintaining product quality. The high-speed rice packaging machine is a testament to technological innovation, enabling manufacturers to package rice quickly and accurately. Let’s explore the versatility of these high-speed rice packing machines.

1. High speed and throughput

High-speed rice packaging machines are designed to operate at blazing speeds, allowing for fast packaging cycles and increased throughput. Capable of packaging 900-1,400 bags per hour, these rice packing machines significantly increase production efficiency, allowing manufacturers to meet tight deadlines and meet high demand.

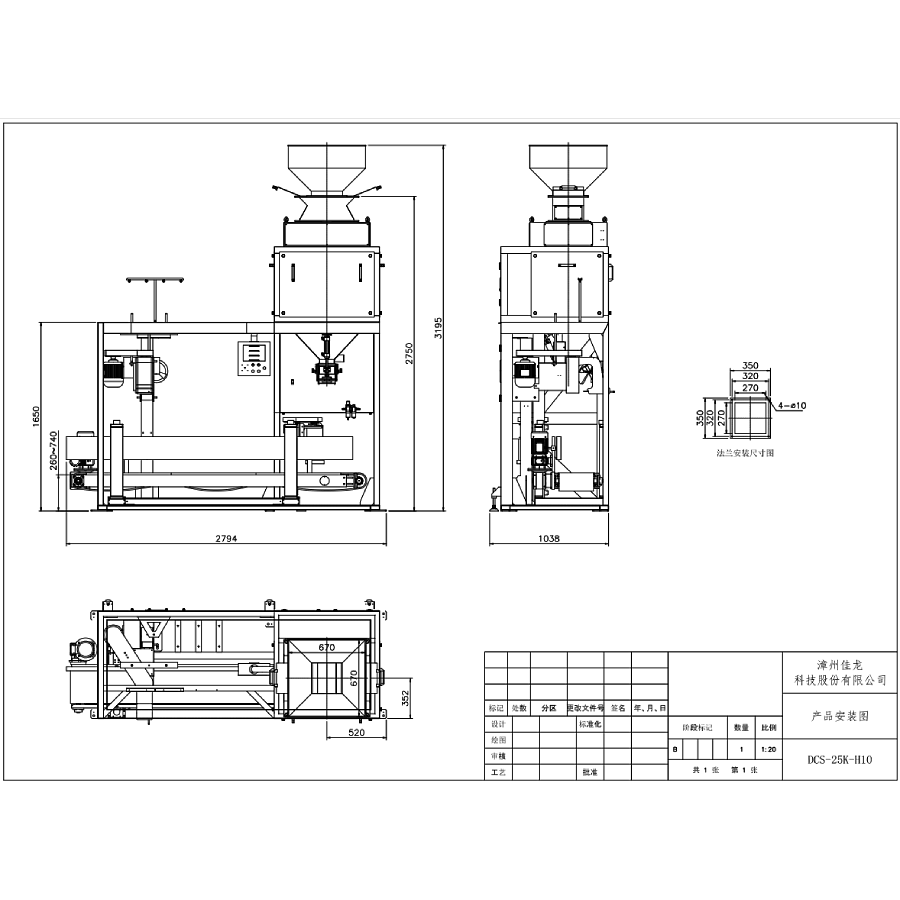

2. Precision weighing system

The precision weighing system is the core of the high-speed rice packaging machine, ensuring accurate distribution of rice into each bag. Advanced sensors and algorithms can accurately measure rice quantity, and can automatically correct errors, over-tolerance, under-tolerance alarms, fault diagnosis and other functions to minimize changes in packaging weight and ensure the consistency of each bag. This level of precision is critical to maintaining quality control and meeting regulatory standards.

3. Automated packaging process

High-speed rice packaging machines automate the packaging process to streamline production and reduce the need for manual labor. From filling and weighing to sealing and labeling, these machines automate every step of the packaging process, minimizing human error and maximizing efficiency. Operators can monitor the entire process from a centralized control panel, ensuring smooth operation and optimal performance.

4. Customizability

One of the main advantages of high-speed rice packaging machines is customizability. The machines can accommodate a variety of rice varieties, packaging sizes and formats, making them suitable for different production requirements. Whether packaging rice, grains, soybeans, peanuts, wheat, feed, millet, corn, seeds, lentils and more, Zhangzhou Jialong can adjust the settings of its automatic rice packing machine to meet customers' specific product specifications and packaging preferences.

5. Seal integrity

Maintaining the quality and integrity of packaged rice is crucial, and high-speed rice packaging machines excel in this regard. Advanced sealing technology and high-quality materials ensure a secure seal, preserving the freshness and flavor of the rice while extending its shelf life. This seal integrity is critical to protecting the product from moisture, contaminants, and other environmental factors that can affect quality.

High-speed rice packaging machines represent the pinnacle of efficiency, precision and reliability in the food packaging industry. These rice packaging machines provide merchants with a competitive advantage in the market due to their superior speed, precise weighing system, automated packaging process and versatility. By simplifying production, improving packaging quality and maximizing efficiency, high-speed rice packaging machines enable manufacturers to meet consumer demands while delivering high-quality rice products to the market.